We use these cookies to gather information about the way users interact with our website..We use this information to create reports and help us improve the website.

Read our Privacy Policy or Cookie Policy

AcceptSolutions

- Solutions

- MDU/High Rise

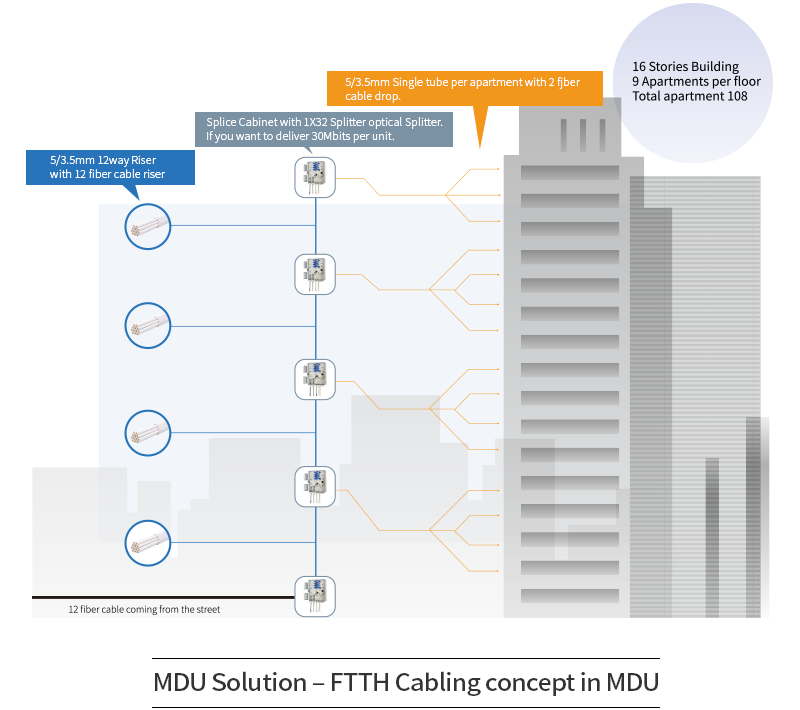

MDU/High Rise

MDU and high-rise buildings often offer the highest subscriber density and can be very rewarding projects but offer unique challenges as well. It is often very difficult or impossible to re-access infrastructure after the building is complete. With other service providers competing for subscribers in the same space, this often means additional material expense for non-subscribers. With microduct preinstalled to each unit fiber drops can be blown in by a single installer as customers take service, saving the majority of material cost until a customer takes service. Pre-connected fibers are available to reduce fiber splicing, further reducing installation cost.

Knet offers a range of low smoke zero halogen (LSZH) options for compliance with national fire and safety regulations. Our solution is scalable to fit any indoor environment from a single-story business park to a high rise and anything in between.

Applications

Low Smoke Zero Halogen

Designed for installation within buildings, it is perfect for applications required to follow strict fire and safety codes with temperature resistance as a priority.

Pre-Cabled

Pre-Cabled Microduct is designed to save the cost & time. ABF/ABC is pre-installed in the KNET Factory during production. This product can be used in a variety of applications.

Direct Install

It’s simple and lightweight structure enables fast and cost- effective installation inside existing conduit. It increases availability of cabling infrastructure by dividing into many smaller tubes.

Specialty Applications

Including hybrid microduct/coax and preconnected air blown fiber (ABF) For connecting to each subscribers, ruggedized and double sheathed duct is offered for drop solution

KNET Microduct Assemblies has been rigorously tested by Telcordia Technologies and found to be compliant to Telcordia GR-3155-CORE.