We use these cookies to gather information about the way users interact with our website..We use this information to create reports and help us improve the website.

Read our Privacy Policy or Cookie Policy

AcceptTechnology & Installation

- Technology & Installation Method

- Direct Install

Direct Install

If an existing conduit pathway can be used, a great deal of time and cost can be saved when installing microducts. Before beginning, you will need to verify that the conduit pathway exists, is in good condition and free of deterioration or cave ins, that adequate access points exist for any branch points, and that there is enough empty space available for use.

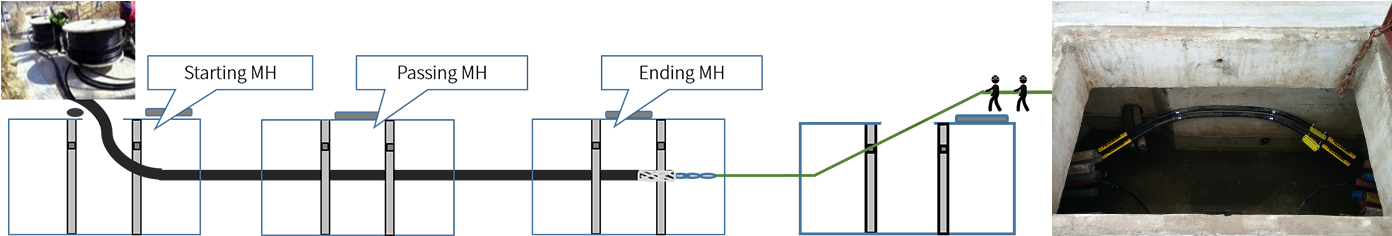

The most common method of pulling microduct through existing conduit is with a winch. To accomplish the installation, the winch will be placed at the destination and the microduct reel at the origination point. A pull string or steel wire will be blown through the conduit using compressed air or pushed through to the origination point. Access holes will be needed at regular intervals due to distance limitations when installing the pull string. Depending on the conditions and the method of installing the pull string access holes may be needed every 200-400 meters. A bend radius limiter should be used to prevent strain on the microducts

It should go without saying, but a vehicle should not be used to replace the winch as it will put too much strain in the microduct and create kinks that will block cable installation later.

When the pull string is through, the bare end of the duct should be covered using an end sleeve or water tight shrink wrap. It is not recommended to use electrical tape for this purpose. Next a pulling grip is slid over the end of the microduct. The pulling grip is a woven cylinder, that when pulled backwards along the microduct, tightens and firmly grips the duct sheath (Think of a Chinese finger trap).

The pulling grip should cover approximately three feet of the microduct end, with very little dead space between the end of the duct and the grip hook. Electrical tape should be used to secure the pulling grip to the duct sheath while the grip is tightened. The attachment loop at the end of the grip hook is now attached to the end of the pull string.

Now the duct is ready to be pulled back through the conduit towards the winch. A swivel ensures that the microduct does not become twisted while being pulled back through the path.

The pulling grip puts a great deal of stress on the microduct near the pulling end. Therefore about 1.8meter of duct should be cut and discarded (twice the length that the pulling grip covers).

KNET Microduct Assemblies has been rigorously tested by Telcordia Technologies and found to be compliant to Telcordia GR-3155-CORE.